This article is part of the

Heat Transfer in Process Plants

series, which explains how heat transfer behavior is translated into

practical design calculations for real equipment.

It follows the earlier discussion of temperature driving forces and LMTD in:

LMTD & Temperature Driving Forces Explained

.

Building on that foundation, this article focuses on what the overall heat

transfer coefficient really represents, and why its assumed value often

determines whether a heat exchanger design succeeds or fails.

The Most Quoted Number in Heat Transfer — and the Most Misunderstood

In process engineering, one symbol appears everywhere:

U — the overall heat transfer coefficient.

It is written on exchanger datasheets.

It is used in sizing calculations.

It is discussed in troubleshooting meetings.

It is blamed when exchangers underperform.

And yet, few thermal concepts are misunderstood as deeply as U.

The confusion usually comes from one simple mistake:

U is treated like a fixed property.

In reality, U is a plant outcome.

This pillar article explains what U really means, how it behaves in real operating plants, and why understanding U properly is essential for designing, operating, and maintaining heat transfer equipment reliably.

Table of Contents

What Is the Overall Heat Transfer Coefficient (U)?

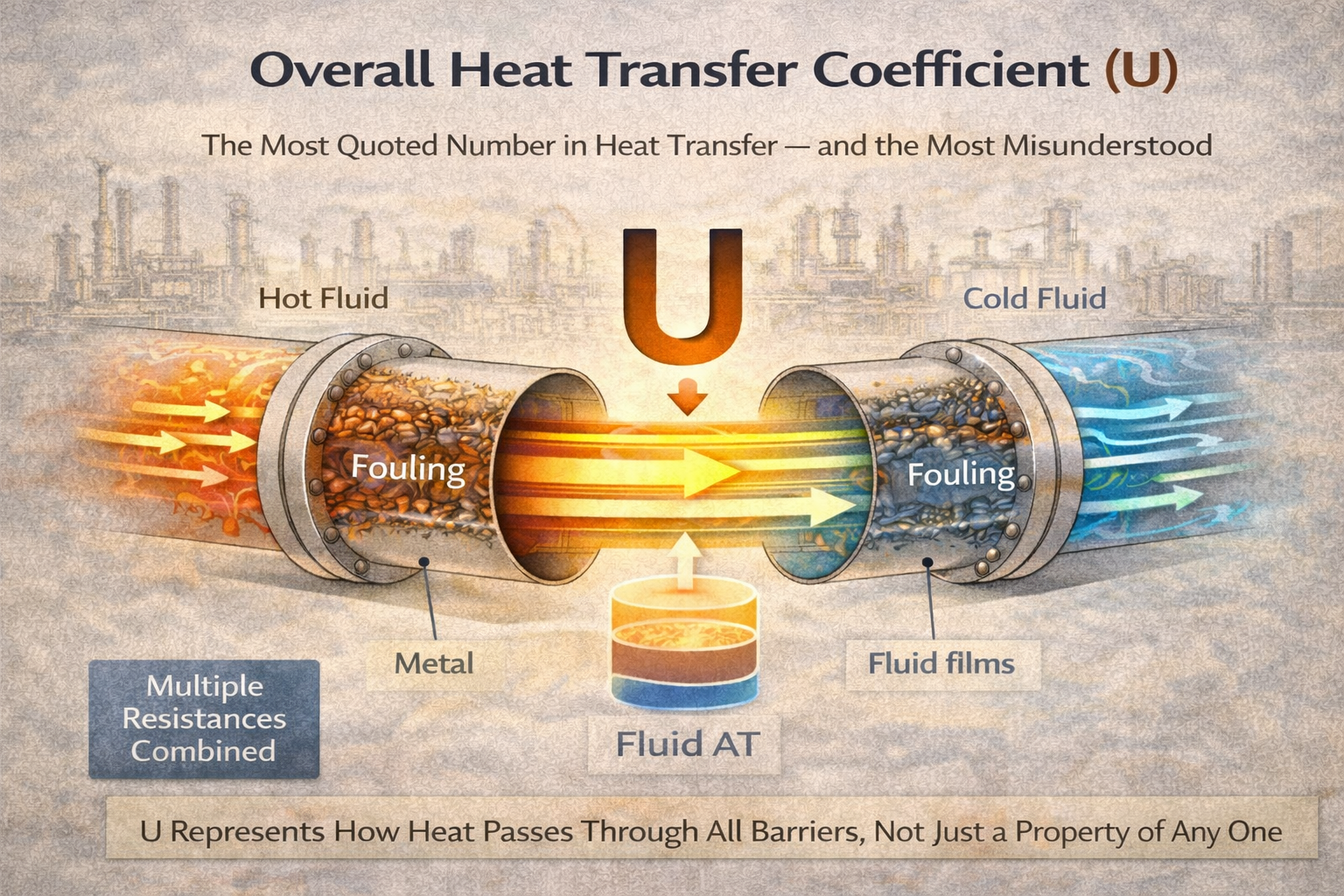

At its simplest, U answers one practical question:

How easily can heat move from one fluid to another through the exchanger wall?

That heat must pass through several barriers:

- Hot fluid film resistance

- Fouling deposits on hot side

- Metal tube or wall resistance

- Fouling deposits on cold side

- Cold fluid film resistance

U combines all of these into one single number.

So U is not a “fluid property.”

It is not a “metal property.”

It is not even an “equipment property.”

U is the total thermal resistance of the whole system, expressed in one lumped value.

Why U Looks Simple in Books but Becomes Complex in Plants

In textbooks, U is presented as a stable coefficient.

In real plants, U behaves more like a living number because it depends on:

- Flow regime

- Fouling history

- Phase change behavior

- Velocity distribution

- Surface condition

- Operating load

- Time

That is why the same exchanger can show:

- High U during commissioning

- Lower U after six months

- Sudden decline after a turnaround

- Different U at summer vs winter conditions

So U is not constant.

U changes because plants change.

What U Actually Represents Physically

The cleanest way to understand U is through resistance.

Heat transfer is not limited by one thing.

It is limited by the weakest link in the resistance chain.

In many exchangers:

- Fluid-side convection dominates

In others: - Fouling dominates

In some: - Phase-change film dominates

U reflects whichever resistance is controlling at that moment.

That is why asking:

“What is the U value of this exchanger?”

is incomplete unless you also ask:

- At what flow rate?

- At what temperature?

- In what fouling condition?

- Under what operating load?

Why Engineers Misuse U So Often

The biggest misconception in industry is this:

Higher U means better exchanger.

Not always.

Because exchanger performance depends on three things:

- U

- Area (A)

- Driving force (ΔT or LMTD)

Even if U is high:

- Pinch points can limit driving force

- Correction factor losses can reduce effectiveness

- Fouling can destroy margin quickly

- Maldistribution can waste surface area

So U alone does not define success.

Plants fail at minimum driving force and maximum resistance — not at average U.

Why U Values from Books Often Fail in Operating Plants

Most handbook U values assume:

- Clean conditions

- Ideal flow distribution

- Stable operation

- Uniform fouling allowance

Plants operate with:

- Deposits

- Aging surfaces

- Load swings

- Seasonal utility variation

- Real maldistribution

So when engineers design directly around book U:

- Area is underestimated

- Fouling margin is consumed early

- Duty is missed sooner than expected

Book U is a starting guess.

Plant U is the truth.

Why U Is Not a Design Input

Many young engineers begin exchanger sizing by selecting a U value first.

This is backward.

Because U cannot be chosen freely.

U depends on:

- Velocity

- Viscosity

- Turbulence

- Fouling condition

- Geometry

- Flow arrangement

Designers control area.

Plants reveal U.

So the correct mindset is:

U is not something you specify.

U is something your exchanger ends up delivering.

That is why U should always be treated as a result.

Clean U vs Dirty U — The Reality of Plant Operation

Designers calculate clean U.

Plants live with dirty U.

The exchanger may meet duty right after cleaning.

But fouling begins immediately:

- Resistance increases

- U decreases

- Utility demand rises

- Control margin shrinks

Most exchangers operate not at clean performance, but at some degraded steady condition.

A design that only works at clean U will never remain reliable.

Robust exchangers are designed for dirty reality.

Why Increasing Area Often Beats Improving U

When exchangers underperform, plants often try to “improve U” by:

- Increasing flow

- Raising turbulence

- Forcing more utility

This usually causes:

- Pressure drop problems

- Vibration and erosion

- Faster fouling

- Operational instability

Area is different.

Area is permanent.

Adding area:

- Reduces heat flux

- Improves fouling tolerance

- Provides margin

- Stabilizes operation

That is why experienced engineers often prefer:

More surface area over optimistic U assumptions.

Owner Perspective: Why U Misunderstanding Becomes Expensive

From a business standpoint, poor U understanding leads to:

- Undersized exchangers

- Frequent emergency cleaning

- Rising utility consumption

- Failed debottlenecking projects

- Premature equipment replacement

Correct understanding of U improves:

- Energy efficiency

- Availability

- Reliability

- Lifecycle cost control

U is not just a design number.

U is an economic driver.

Final Perspective

Overall heat transfer coefficient is one of the most quoted numbers in process engineering.

But it is not a constant.

It is not a guarantee.

It is not a design target.

U is the plant’s response to:

- flow

- fouling

- geometry

- time

- resistance

Engineers who understand U correctly design exchangers that keep working long after startup.

Those who chase U values often spend years trying to recover performance that was never truly guaranteed.

Understanding U — meaning, reality, and plant behavior is one of the clearest steps from textbook engineering to real plant engineering.

We have discussed what the overall heat transfer coefficient really means in plant operation and why it is never a single fixed property of an exchanger.

How U Is Built from Film + Wall + Fouling Resistances

This article explains how convection films, metal walls, and fouling layers combine to form the overall U value — and why the controlling resistance is rarely the one engineers assume.