This article is part of the

Heat Transfer in Process Plants

series, which examines how different heat transfer mechanisms behave

in real process equipment.

It builds on the broader discussion of radiation heat transfer in:

Radiation Heat Transfer in Process Plants

.

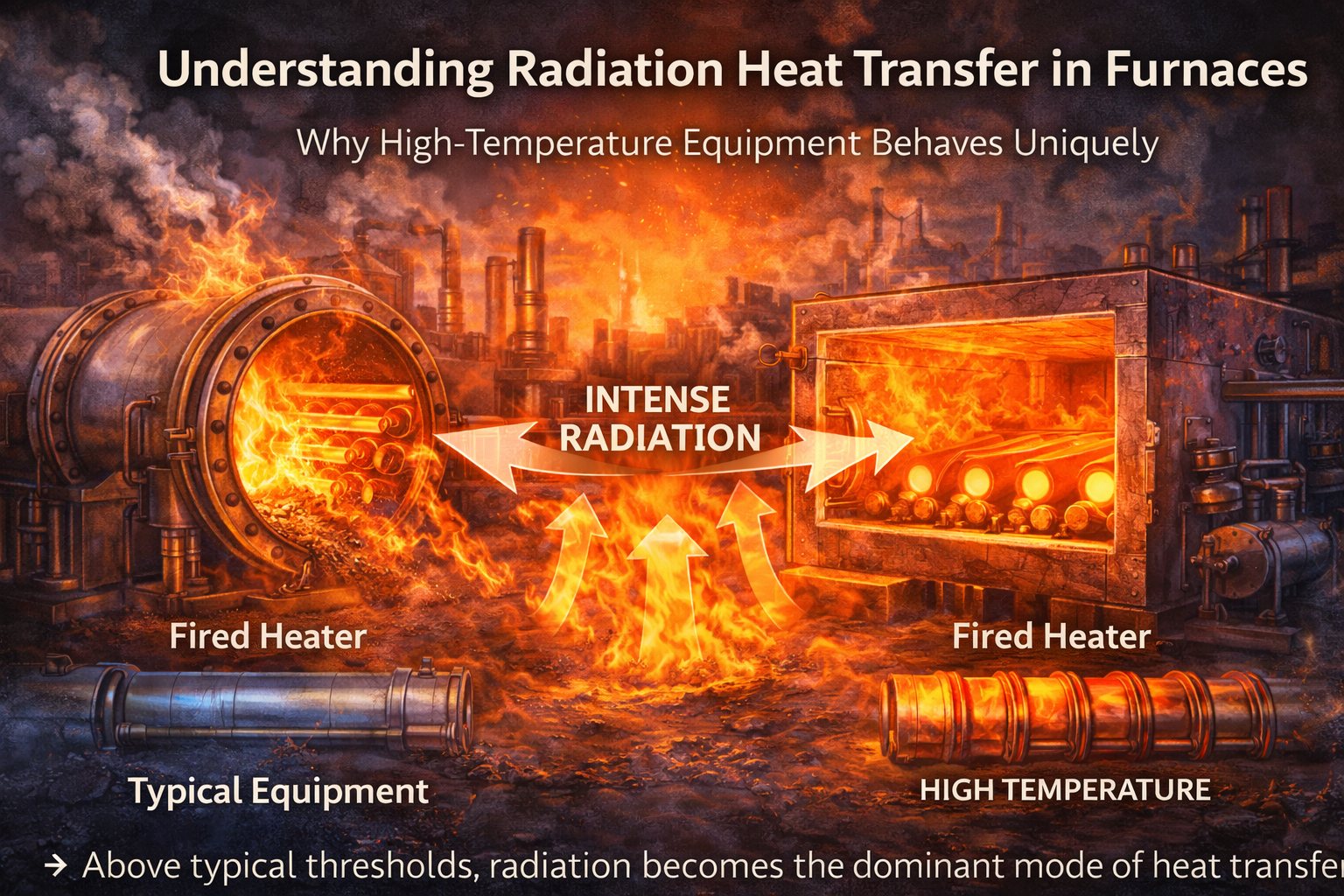

This article narrows the focus to furnaces and fired equipment, where

radiation typically dominates heat transfer and strongly influences

performance and safety.

The Primary Heat Transfer Mechanism in Fired Process Equipment

In fired heaters and furnaces, heat transfer behaves very differently from most other process equipment. Conduction and convection are still present, but they do not define performance in the same way they do in exchangers, reactors, or piping.

In furnaces, radiation is the dominant heat transfer mechanism.

Understanding radiation heat transfer in furnaces is essential for explaining:

- why furnace geometry matters so much,

- why tube metal temperature limits firing rates,

- why small changes in operation can cause large thermal effects,

- why furnace design is as much art as calculation.

This article explains how radiation actually works in furnaces and why it governs their behavior.

Table of Contents

Why Furnaces Are Radiation-Dominated Systems

Furnaces operate at very high temperatures.

Flames, refractory walls, and hot combustion gases all reach temperatures where radiant energy emission becomes intense.

At these temperatures:

- radiation heat flux increases rapidly,

- convection becomes secondary,

- conduction plays a minor role in overall heat transfer.

As a result, most of the heat transferred from the flame to the process tubes occurs by radiation, not by convection from hot gases.

This is the defining feature of fired equipment.

Sources of Radiant Heat in Furnaces

Radiation in furnaces comes from multiple sources.

Flame Radiation

The flame itself emits radiant energy due to:

- excited gas molecules,

- incandescent particles,

- chemical reactions occurring at high temperature.

Flame radiation is highly directional and sensitive to flame shape, length, and stability.

Hot Gas Radiation

Combustion gases at high temperature also emit radiation, especially when they contain radiating species such as CO₂ and H₂O.

Although weaker than flame radiation, gas radiation contributes significantly over large furnace volumes.

Refractory and Wall Radiation

Furnace walls absorb radiant energy and re-emit it.

This secondary radiation:

- smooths heat distribution,

- contributes to tube heating,

- depends strongly on refractory temperature and emissivity.

In many furnaces, wall radiation provides a substantial portion of the total radiant heat transfer.

How Radiant Heat Reaches Process Tubes

Radiant heat transfer occurs through line-of-sight.

Heat moves directly from:

- flame to tube,

- wall to tube,

- hot gas volume to tube.

No physical contact is required.

This explains why:

- tube spacing affects heat flux,

- shadowing reduces heat transfer,

- tube arrangement is critical to furnace performance.

Unlike convection, radiation does not depend on fluid velocity around the tube.

Radiant Section vs Convective Section

Fired heaters are usually divided into:

- a radiant section,

- a convective section.

In the radiant section:

- radiation dominates heat transfer,

- tube metal temperature is highest,

- heat flux is intense and directional.

In the convective section:

- gas temperature is lower,

- convection becomes more important,

- radiation still exists but is less dominant.

Understanding this distinction explains why:

- tube failures usually occur in radiant sections,

- firing rate limits are set by radiant section constraints,

- convective banks recover waste heat rather than define capacity.

Why Tube Metal Temperature Is the Limiting Factor

In furnaces, the process fluid temperature is not usually the limiting parameter.

Tube metal temperature is.

Radiation heats the tube surface directly.

If radiant heat flux is too high:

- tube metal overheats,

- metallurgical limits are exceeded,

- creep, oxidation, and failure occur.

This is why:

- firing rates are limited,

- excess air is controlled,

- flame shape is carefully managed.

Radiation sets the safe operating envelope.

Effect of Flame Shape and Burner Operation

Radiant heat transfer depends strongly on flame behavior.

Changes in:

- flame length,

- flame impingement,

- burner alignment,

- air-fuel ratio,

directly affect radiation patterns.

This explains why:

- poor burner tuning causes hot spots,

- flame impingement leads to rapid tube damage,

- unstable flames create uneven heating.

Furnace operation is therefore inseparable from radiation control.

Role of Refractory in Radiation Heat Transfer

Refractory is not just insulation.

It plays an active role in radiation by:

- absorbing flame radiation,

- re-emitting energy uniformly,

- influencing wall temperature.

High-emissivity refractory:

- improves heat distribution,

- reduces local hot spots,

- stabilizes furnace operation.

Damaged or degraded refractory:

- alters radiation patterns,

- increases heat loss,

- raises tube metal temperature.

Refractory condition directly affects furnace thermal performance.

Why Geometry Matters So Much in Furnaces

Radiation is highly sensitive to geometry.

Factors such as:

- furnace width and height,

- tube spacing,

- burner location,

- wall distance,

all influence how radiation reaches process tubes.

This explains why:

- furnaces with identical duty perform differently,

- revamps require careful thermal analysis,

- layout changes have large consequences.

Radiation does not average out like convection.

It depends on what each surface “sees.”

Radiation During Startup and Transients

Radiation responds instantly to temperature changes.

During startup:

- flame temperature rises quickly,

- radiant heat flux increases sharply,

- tube metal heats faster than fluid.

During upsets:

- firing changes cause immediate thermal response,

- radiation spikes can damage tubes.

This is why:

- controlled firing ramps are essential,

- startup procedures are conservative,

- rapid changes are avoided.

Radiation has no inertia.

It reacts immediately.

Why Radiation Is Difficult to Balance

In furnaces, balancing heat transfer is challenging because:

- radiation depends on temperature to a high power,

- emissivity changes with surface condition,

- flame behavior is not perfectly predictable,

- geometry effects are complex.

As a result:

- simplified calculations are used,

- conservative margins are applied,

- operational experience is critical.

Radiation design is inherently less forgiving than convection design.

Safety Implications of Radiation in Furnaces

Radiant heat poses direct safety risks.

High radiant flux can:

- overheat nearby equipment,

- damage structural steel,

- expose personnel to burn risk,

- degrade insulation and coatings.

This is why:

- minimum approach distances are specified,

- shielding is used,

- access during operation is restricted.

Radiation control is both a thermal and safety requirement.

Owner Perspective: Why Radiation Governs Furnace Economics

From an ownership viewpoint, radiation affects:

- fuel efficiency,

- tube life,

- maintenance frequency,

- unplanned shutdown risk.

Radiation-related damage is often expensive and sudden.

Plants that understand and manage radiation:

- extend tube life,

- operate closer to optimal efficiency,

- reduce risk of catastrophic failure.

Few factors influence furnace reliability as strongly as radiation.

Final Perspective

In furnaces, radiation is not one heat transfer mode among many.

It is the primary mechanism.

It defines tube metal temperature, limits firing rate, shapes geometry, and governs safety.

Ignoring radiation in furnace design or operation is not a simplification.

It is a risk.

Understanding radiation does not require complex mathematics.

It requires respect for how energy behaves at high temperature.

And that understanding is essential for anyone responsible for fired process equipment.

Furnaces represent the most obvious case where radiation dominates heat

transfer due to high temperatures and large radiating surfaces.

The next step is to recognize that radiation also plays a decisive role in

many plant situations where it is often underestimated or overlooked.

When Radiation Cannot Be Ignored

This article highlights common plant scenarios where radiation quietly

governs heat transfer, explains why ignoring it leads to design and

operational errors, and shows when engineers must account for radiation

explicitly.