This article is part of the Heat Transfer in Process Plants series, which examines how different heat transfer mechanisms govern behavior and performance in real process equipment.

It follows the earlier discussion on fluid-driven heat transfer in:

Convection in Process Plants

.

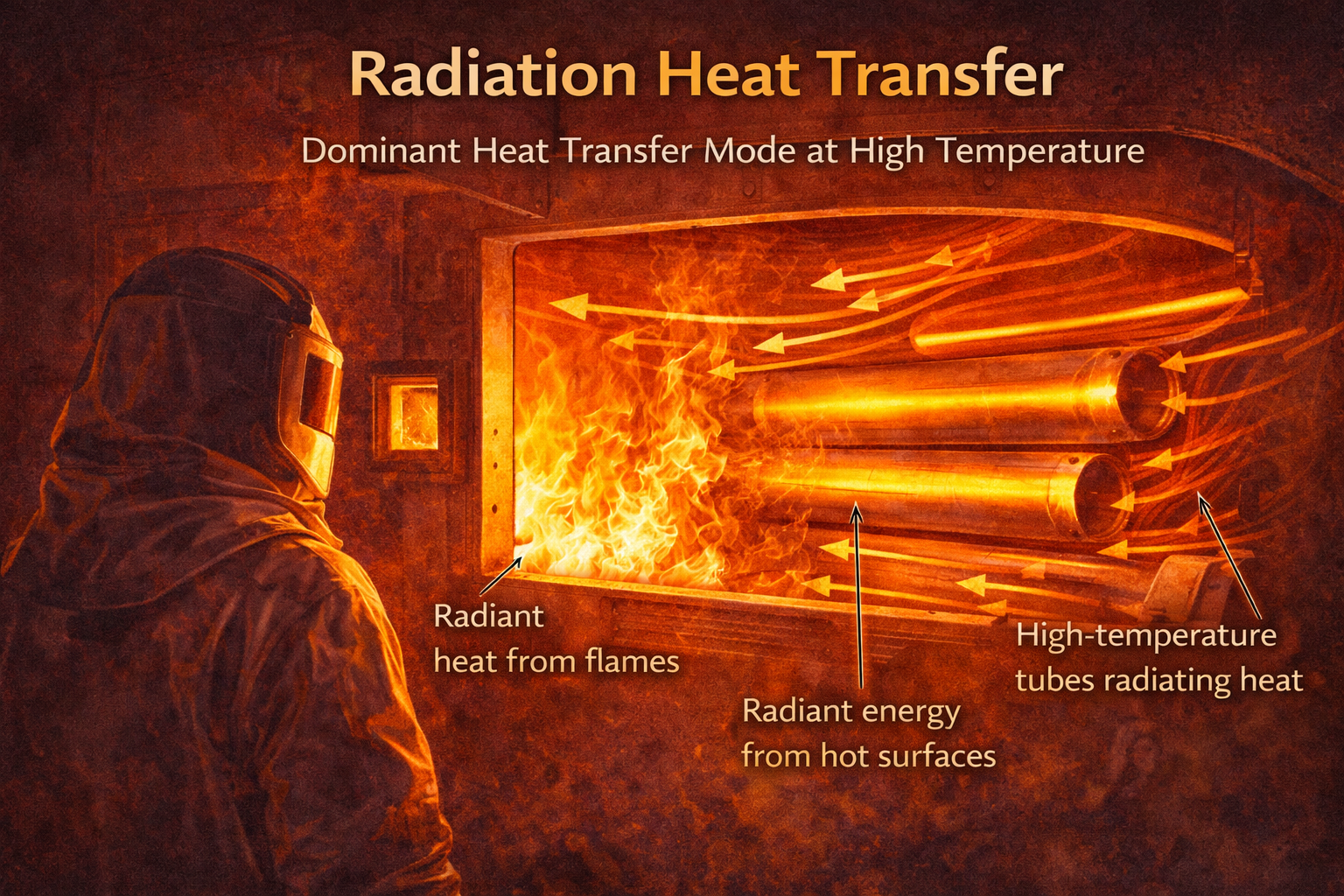

Building on that foundation, this article focuses on how radiation becomes dominant in high-temperature and fired process systems.

The Heat Transfer Mode That Quietly Dominates at High Temperature

In most process plants, heat transfer discussions focus on conduction and convection. These modes govern the majority of equipment operating at moderate temperatures, where fluids are in motion and metal walls respond predictably.

Radiation behaves differently.

It does not require contact.

It does not require fluid motion.

It does not slow down when flow stops.

At elevated temperatures, radiation becomes a governing heat transfer mechanism, often dominating overall heat exchange even when it is not explicitly designed for.

This article explains what radiation heat transfer means in process plants, where it becomes important, and why misunderstanding it leads to design errors, operational surprises, and safety concerns.

Table of Contents

What Radiation Heat Transfer Really Is

Radiation is heat transfer by electromagnetic energy.

Unlike conduction and convection:

- it does not require a medium,

- it does not require material contact,

- it travels directly from one surface to another.

Any surface at a temperature above absolute zero emits radiant energy.

In process plants, radiation becomes significant when:

- surface temperatures are high,

- large exposed areas exist,

- line-of-sight between hot and cold surfaces is present.

Radiation is always occurring.

At low temperatures, its effect is small.

At high temperatures, it dominates.

Why Radiation Is Different from Other Heat Transfer Modes

Radiation behaves fundamentally differently from conduction and convection.

Key distinctions include:

- heat transfer increases rapidly with temperature,

- surface condition matters more than material thickness,

- geometry and orientation strongly affect heat exchange,

- insulation effectiveness depends on emissivity, not just thickness.

This difference explains why radiation is often underestimated during design and then encountered unexpectedly during operation.

Where Radiation Appears in Process Plants

Radiation is not limited to furnaces.

It appears wherever high temperatures and exposed surfaces exist.

Common locations include:

- fired heaters and furnaces,

- reformers and cracking units,

- hot reactors,

- incinerators,

- flare systems,

- hot piping and valves,

- uninsulated or poorly insulated equipment.

In these systems, radiation can account for a major fraction of total heat transfer.

Radiation in Fired Equipment

In furnaces and fired heaters:

- flame radiation,

- gas radiation,

- wall radiation,

together dominate heat transfer to process tubes.

Convective heat transfer still occurs, but radiation usually provides the largest contribution to heat flux.

This is why:

- tube spacing matters,

- flame shape affects performance,

- refractory condition is critical,

- radiant section design governs duty.

Radiation defines both efficiency and tube metal temperature in fired equipment.

Radiation from Hot Equipment Surfaces

Even outside fired equipment, hot surfaces radiate significant energy.

Examples include:

- reactor shells operating at high temperature,

- hot oil piping,

- exhaust ducts,

- furnace casings.

This radiation affects:

- nearby equipment,

- operating personnel,

- insulation performance,

- ambient temperature in operating areas.

Ignoring this effect leads to safety risks and unexpected heat loss.

Why Radiation Increases Rapidly with Temperature

One of the most important characteristics of radiation is its strong temperature dependence.

As surface temperature increases:

- radiant heat emission rises dramatically,

- small temperature increases cause large heat flux changes.

This explains why:

- radiation is negligible at low temperatures,

- radiation dominates at high temperatures,

- fired equipment behavior is highly sensitive to operating temperature.

This sensitivity makes radiation both powerful and dangerous if misunderstood.

Role of Surface Properties

Radiation depends heavily on surface condition.

Key factors include:

- emissivity,

- surface roughness,

- oxidation,

- fouling.

Two surfaces at the same temperature can radiate very different amounts of heat depending on surface finish.

This explains why:

- oxidized metal radiates more than polished metal,

- refractory behaves differently from bare steel,

- insulation jacketing affects heat loss.

Radiation is governed more by surface condition than by bulk material properties.

Geometry and Line-of-Sight Effects

Radiation depends on what surfaces “see” each other.

Heat exchange by radiation occurs only when:

- surfaces have a clear line-of-sight,

- view factors are favorable.

This explains why:

- tube arrangement matters in furnaces,

- shielding reduces radiant heat exposure,

- equipment orientation affects heat loss.

Unlike conduction and convection, radiation is highly directional.

Radiation During Normal Operation vs Transients

Radiation plays different roles during steady operation and transients.

During normal operation:

- radiation establishes steady heat flux,

- surface temperatures stabilize.

During startup or upset:

- temperature changes rapidly,

- radiation responds immediately,

- heat flux spikes occur.

This explains why:

- startup procedures limit firing rates,

- rapid temperature changes increase tube damage risk,

- thermal stress is severe during transients.

Radiation reacts instantly to temperature changes.

Why Radiation Is Often Underestimated

Radiation is frequently underestimated because:

- it is invisible,

- it is difficult to visualize,

- it is harder to calculate accurately,

- it interacts with geometry and surface condition.

Designers often rely on simplified assumptions.

Operators often rely on experience.

When these assumptions fail, radiation-related issues appear suddenly.

Consequences of Ignoring Radiation

Ignoring radiation effects leads to:

- underestimated heat loss,

- overheated tube metal,

- insulation failure,

- unsafe operating areas,

- unexpected energy consumption.

These problems are often misattributed to:

- poor convection,

- material failure,

- operational mistakes.

In reality, radiation is the controlling mechanism.

Radiation and Safety

Radiation has direct safety implications.

High radiant heat flux can:

- cause burns without contact,

- overheat adjacent equipment,

- degrade structural materials,

- accelerate insulation damage.

Safety distances, shielding, and insulation design all depend on radiation analysis.

Radiation control is as much a safety issue as it is a thermal one.

Owner Perspective: Why Radiation Affects Cost and Reliability

From an ownership standpoint, radiation influences:

- fuel efficiency,

- tube life,

- maintenance frequency,

- safety compliance,

- energy loss.

Radiation-related damage often leads to:

- premature tube replacement,

- unplanned shutdowns,

- high repair cost.

Understanding radiation helps owners:

- protect assets,

- reduce risk,

- improve long-term reliability.

Final Perspective

Radiation is not a secondary heat transfer mode in high-temperature systems.

It is often the dominant mechanism.

It responds instantly to temperature changes, depends strongly on surface condition, and ignores fluid motion entirely.

Plants that understand radiation:

- design safer equipment,

- operate within realistic limits,

- avoid premature failures.

Plants that underestimate it:

- face unexpected damage,

- struggle with efficiency,

- accept unnecessary risk.

This understanding is not advanced theory.

It is essential plant reality.

And it completes the foundation of practical heat transfer in process plants.

We have discussed how radiation governs heat transfer at high temperatures and why surface properties, geometry, and view factors matter in process plants.

The next step is to focus on where radiation dominates most clearly and decisively in real facilities.

Radiation Heat Transfer in Furnaces

This article explains how radiative heat transfer controls performance inside fired heaters and furnaces, why convection becomes secondary at high temperatures, and where design and operation directly influence radiant heat transfer.