This article is part of the Heat Transfer in Process Plants series, which explains how real operating limitations affect heat-transfer performance over time.

It builds on the broader discussion of fouling and degradation in:

Heat Transfer Limitations, Fouling & Degradation

.

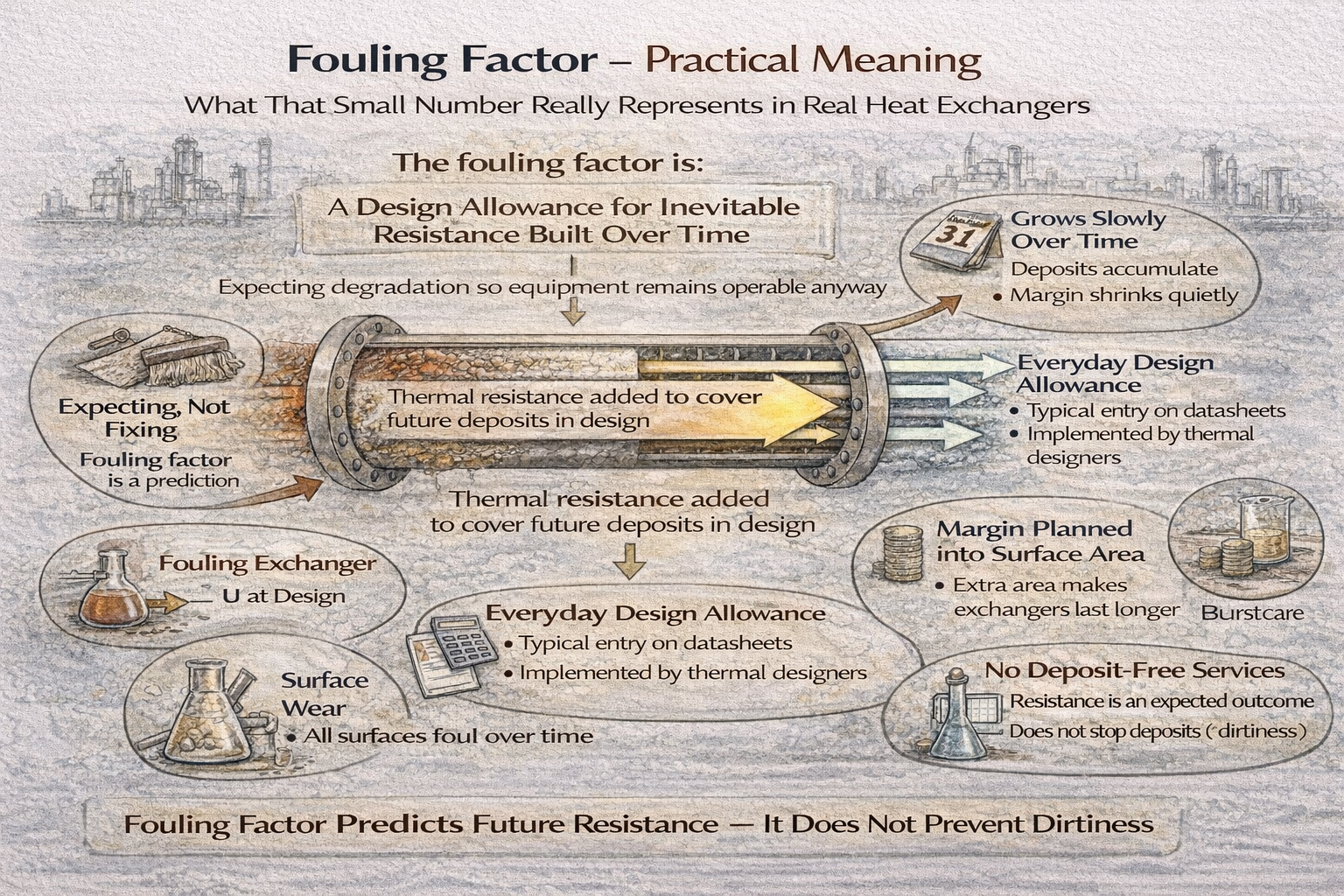

This article focuses specifically on the practical meaning of fouling factor, why it is included in design, and how it relates to performance decline in real exchangers.

What That Small Number Really Represents in Real Heat Exchangers

The fouling factor is one of the most misunderstood entries in a heat exchanger datasheet.

It is often:

- copied from standards,

- accepted without discussion,

- treated as a conservative safety margin.

In operating plants, however, the fouling factor is rarely understood for what it truly represents:

an allowance for inevitable performance loss over time.

This article explains the practical meaning of fouling factor, why it exists, what it does — and just as importantly, what it does not do — in real process plants.

Table of Contents

What Fouling Factor Is — in Simple Terms

At its core, the fouling factor represents:

Additional thermal resistance expected to develop due to deposits on heat transfer surfaces

It is not a prediction of fouling thickness.

It is not a measure of dirtiness.

It is not a guarantee of performance.

It is a design allowance for degradation that designers expect will occur during normal operation.

Fouling Factor Is a Resistance, Not a Layer

One of the most common misunderstandings is imagining fouling factor as a physical layer of known thickness.

In reality:

- fouling factor represents resistance, not geometry,

- different deposits with different thicknesses can produce the same resistance,

- surface roughness and contact resistance matter more than thickness alone.

A thin, poorly conducting deposit can have a larger effect than a thick but conductive one.

This is why fouling behavior is difficult to predict precisely.

Why Fouling Factor Exists in Design

Designers include fouling factor because they know that:

- clean conditions are temporary,

- surfaces will degrade,

- resistance will increase.

Without fouling factor:

- exchangers would be sized for day-one performance only,

- capacity would be lost almost immediately,

- plants would operate permanently at the edge of feasibility.

Fouling factor is not pessimism.

It is realism.

Fouling Factor Is Not a “Free Margin”

A dangerous misconception is treating fouling factor as unused margin that can be consumed safely.

In reality:

- fouling factor assumes normal fouling behavior,

- it is consumed gradually during operation,

- once fully consumed, no buffer remains.

Operating beyond this point does not “use extra margin” — it forces operation into unsafe or unstable territory.

Why Fouling Factor Does Not Prevent Fouling Problems

Including fouling factor does not mean fouling will stop being a problem.

It only means:

- the exchanger can tolerate a certain amount of fouling before performance loss becomes critical.

If fouling develops faster or unevenly:

- performance issues appear earlier,

- local hot spots develop,

- control problems arise.

Fouling factor assumes average behavior, not worst-case reality.

Fouling Factor Does Not Represent Operating Cleanliness

A low fouling factor does not mean the service is “clean.”

A high fouling factor does not mean it is “dirty.”

It reflects:

- expected deposition tendency,

- historical experience,

- industry practice.

Two services with identical fouling factors can behave very differently depending on:

- chemistry,

- temperature profile,

- flow regime,

- shutdown frequency.

Fouling factor is a planning assumption, not a cleanliness metric.

Why Fouling Factor Is Service-Specific but Plant-Dependent

Standards often provide recommended fouling factors for services.

These values are:

- averages across many plants,

- based on historical data,

- not tailored to your specific operation.

In practice:

- the same service fouls differently in different plants,

- operating discipline and chemistry matter,

- temperature excursions accelerate fouling.

Blindly applying standard fouling factors can either:

- under-protect performance, or

- over-inflate capital cost.

Judgment is required.

Fouling Factor Is Distributed — Not Uniform

Design calculations treat fouling factor as evenly distributed.

In reality:

- fouling is localized,

- hot zones foul faster,

- low-velocity regions accumulate deposits,

- maldistribution creates uneven resistance.

This explains why:

- exchangers underperform even when “average” fouling seems acceptable,

- cleaning improves some areas but not others,

- performance does not recover fully after cleaning.

Uniform fouling is a design convenience, not a plant reality.

Fouling Factor Is Slowly Consumed, Then Suddenly Felt

Early in exchanger life:

- fouling factor consumption is invisible,

- utilities compensate quietly,

- performance appears stable.

As resistance accumulates:

- temperature driving force margin shrinks,

- sensitivity increases,

- control tightens.

When fouling factor is nearly exhausted:

- small additional fouling causes large performance loss,

- problems appear suddenly.

This delayed response is why fouling feels unpredictable.

Why Fouling Factor Should Influence Cleaning Strategy

Fouling factor is not just a design input.

It should inform:

- expected cleaning intervals,

- energy penalty evaluation,

- availability planning.

Cleaning too early:

- wastes availability,

- increases cost,

- exposes equipment to damage.

Cleaning too late:

- forces operation near limits,

- risks sudden failure,

- increases energy consumption.

Understanding fouling factor helps optimize this balance.

Owner Perspective: Fouling Factor Is an Economic Assumption

From an ownership standpoint, fouling factor represents:

- expected performance decay,

- planned energy inefficiency,

- tolerated resistance growth.

Underestimating it leads to:

- frequent outages,

- lost production,

- reactive maintenance.

Overestimating it leads to:

- unnecessary capital spending,

- oversized equipment,

- reduced efficiency.

The right fouling factor aligns capital cost with lifecycle reality.

Final Perspective

Fouling factor is not a technical footnote.

It is a recognition that heat transfer equipment lives in the real world — not in steady, clean, ideal conditions.

Understanding its practical meaning helps engineers:

- design more robust exchangers,

- operate with fewer surprises,

- make better cleaning and revamp decisions.

Fouling factor does not prevent fouling.

It prepares the plant to live with it.

And that preparation is essential for reliable, economical heat transfer in real process plants.

Understanding what the fouling factor represents is only the starting point. The next question is why designers deliberately build extra allowance into exchanger sizing beyond clean performance.

Fouling margin is not just a conservative habit — it reflects the reality that exchangers rarely remain clean in operation.

Why Designers Add Fouling Margin

This article explains why fouling margin is included in real design work, how it protects long-term duty, and why underestimating it leads to early performance loss and repeated plant interventions.