This article is part of the Heat Transfer in Process Plants series, which explains how real operating factors impose performance limits on heat exchangers over time.

It builds directly on the practical meaning of fouling factor discussed in:

Fouling Factor – Practical Meaning

.

This article explains why designers include fouling margin in exchanger sizing, what it protects against, and how it affects long-term plant operation and maintenance.

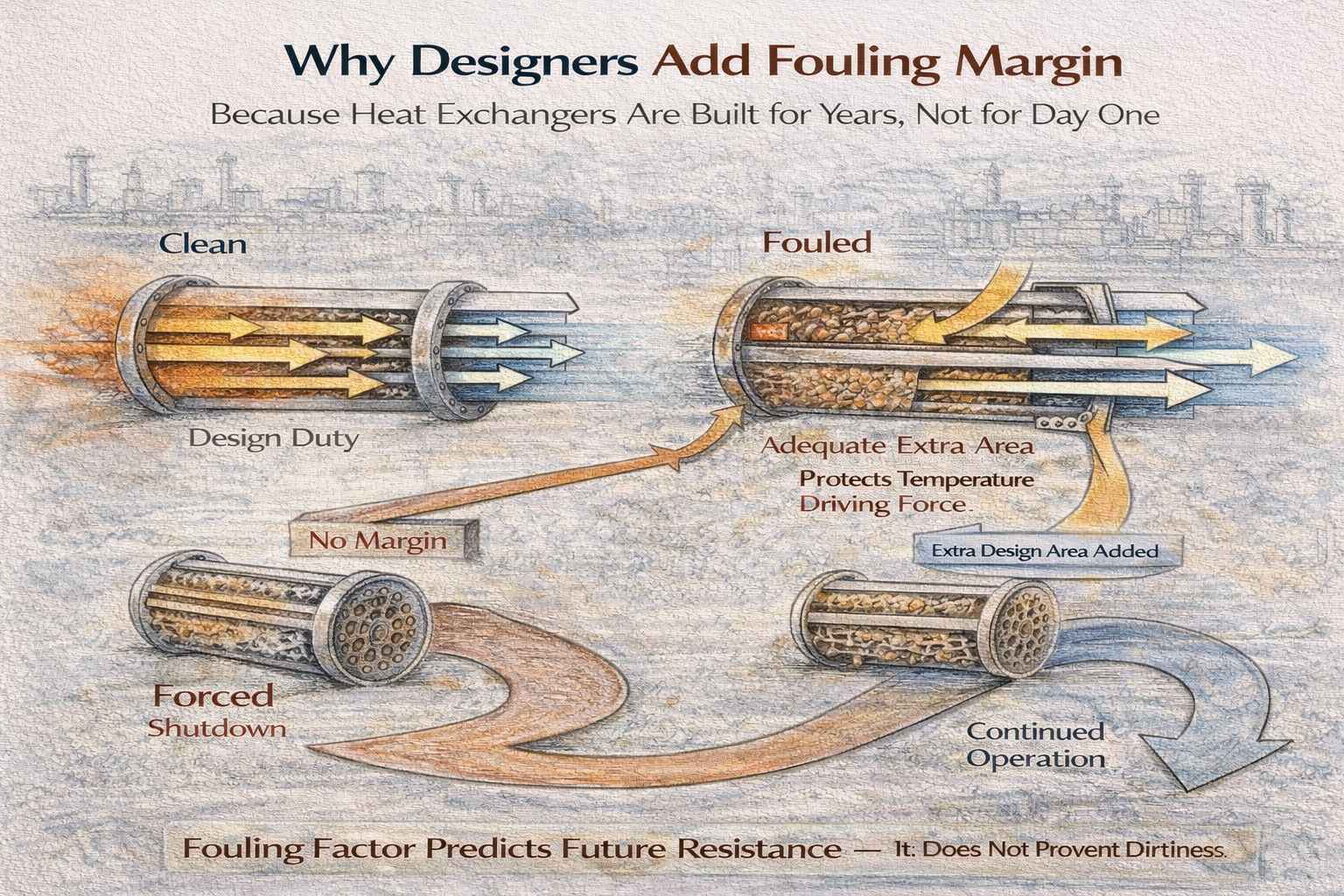

Because Heat Exchangers Are Built for Years, Not for Day One

In almost every heat exchanger design, some form of fouling margin is added.

To many readers, this looks like:

- conservatism,

- overdesign,

- unnecessary capital cost.

In real plants, fouling margin is something else entirely.

It is the difference between equipment that works briefly and equipment that keeps working.

Fouling margin in heat exchangers is not conservatism — it is a realistic allowance for inevitable resistance buildup over years of plant operation.

This article explains why designers deliberately add fouling margin, what that margin really protects against, and why exchangers without adequate fouling margin almost always become operational problems.

Table of Contents

Fouling Margin Exists Because Fouling Is Certain

Designers add fouling margin for one fundamental reason:

Fouling will occur.

Not might.

Not occasionally.

Not only in badly operated plants.

In every real process plant:

- deposits form,

- resistance increases,

- heat transfer degrades.

Designing without fouling margin is equivalent to designing for a condition that will not last.

Fouling Margin Is Not About Dirt — It Is About Time

A common misunderstanding is that fouling margin exists because fluids are “dirty.”

In reality, fouling margin exists because time passes.

Even with:

- clean feeds,

- good filtration,

- careful operation,

surfaces change over time due to:

- chemical reactions,

- surface aging,

- micro-scale deposition,

- corrosion by-products.

Fouling margin is a time buffer, not a cleanliness assumption.

Why Clean Performance Is a Short-Lived Condition

At startup or immediately after cleaning:

- heat transfer surfaces are relatively clean,

- resistance is low,

- performance looks excellent.

This condition is temporary.

As operation continues:

- fouling resistance grows,

- U declines,

- required driving force increases.

Designs that only meet duty at clean conditions begin losing margin almost immediately.

Fouling margin ensures that acceptable performance extends well beyond startup.

Fouling Margin Protects Temperature Driving Force

One of the most important roles of fouling margin is protecting temperature driving force.

As fouling develops:

- resistance increases,

- more ΔT is required for the same duty.

Without margin:

- approach temperatures tighten quickly,

- pinch conditions appear,

- control becomes unstable.

Fouling margin delays this collapse, allowing the exchanger to operate comfortably for longer periods.

Why Fouling Margin Is Added as Area, Not as U

Experienced designers rarely rely on fouling margin by “hoping U stays high.”

Instead, fouling margin is usually added as:

- extra surface area,

- allowance for resistance growth.

This is because:

- U will degrade regardless,

- area does not degrade.

Adding area creates passive robustness.

It does not depend on:

- operating discipline,

- control precision,

- perfect chemistry.

It simply exists.

Fouling Margin Is Not Meant to Be Fully Used Every Day

Another common misunderstanding is treating fouling margin as something that should be fully consumed in normal operation.

In reality:

- fouling margin represents a limit, not a target,

- operating close to that limit is undesirable,

- best operation occurs well before margin exhaustion.

When fouling margin is fully consumed:

- energy consumption is high,

- control margins are thin,

- risk increases sharply.

Designers add margin so that plants do not live permanently at the edge.

Fouling Margin Reflects Uncertainty

Designers never know exactly:

- how fast fouling will develop,

- where it will concentrate,

- how operating practices will evolve,

- how feed quality will change.

Fouling margin absorbs this uncertainty.

It protects the plant from:

- optimistic assumptions,

- future operating changes,

- gradual degradation that no one notices day-to-day.

Margin is not a prediction.

It is insurance.

Why Fouling Margin Is Often the First Thing Questioned

During cost reviews, fouling margin is often challenged because:

- it increases exchanger size,

- it increases capital cost,

- its benefit is not immediately visible.

This creates pressure to reduce margin.

Plants that remove fouling margin often:

- save capital initially,

- lose far more in operation,

- spend years compensating with utilities and maintenance.

The cost of margin is paid once.

The cost of no margin is paid repeatedly.

Fouling Margin and Cleaning Strategy Are Linked

Fouling margin determines:

- how long the exchanger can operate before cleaning becomes necessary,

- how sensitive performance is to fouling growth,

- how urgently cleaning must be scheduled.

With adequate margin:

- cleaning can be planned economically,

- outages are predictable,

- availability improves.

Without margin:

- cleaning becomes reactive,

- outages disrupt production,

- availability suffers.

Design choices shape maintenance behavior for years.

Why Fouling Margin Is Not Conservatism

Adding fouling margin is often labeled as conservative design.

In reality, it is experienced design.

Conservative design avoids risk by oversizing everything indiscriminately.

Experienced design:

- adds margin where degradation is inevitable,

- avoids chasing optimistic performance,

- balances capital cost against lifecycle cost.

Fouling margin is targeted realism, not blanket conservatism.

Owner Perspective: Fouling Margin Protects Long-Term Value

From an ownership standpoint, fouling margin:

- reduces forced outages,

- stabilizes energy consumption,

- improves predictability,

- lowers lifecycle cost.

Plants without adequate fouling margin often:

- operate under constant stress,

- consume excess utilities,

- face frequent interventions.

The exchanger may be cheaper to build — but more expensive to own.

Final Perspective

Designers add fouling margin because they understand something fundamental:

Heat exchangers do not operate in ideal, clean, frozen conditions.

They operate in plants — with time, chemistry, variability, and compromise.

Fouling margin is the quiet buffer that allows equipment to age without becoming a problem.

It is not excess.

It is foresight.

And foresight is what separates exchangers that merely start up from exchangers that continue to perform reliably year after year.

Adding fouling margin is an attempt to protect exchanger performance over time, but the real challenge is that fouling rarely appears suddenly or visibly.

In most plants, fouling degrades heat transfer quietly, reducing duty and efficiency long before anyone notices a clear failure.

The upcoming article, How Fouling Silently Destroys Performance, explains how small deposits compound into major thermal resistance, why performance loss is often gradual and misinterpreted, and how plants can recognize fouling effects before they become operational crises.